Precision engineering is an art form. There are many ways to make a case. Here at Dievas, we take extra steps to make sure all the fine details are in place. From the smooth BUT straight edges to the smooth interaction between the case, bezel, caseback and parts.It will be like a factory tour where we take you through the different stages of manufacturing all from the comfort of your home and also some sneak peaks and behind the scene never shown before by other manufacturers.This is also to further emphasize that our watches are well engineered and masterpieces which we can truly call MADE IN GERMANY.

Dievas in renown watchmaking central at the gateway of Black Forrest, 30mins from Stuttgart.

The road leading to our manufacturing facilities

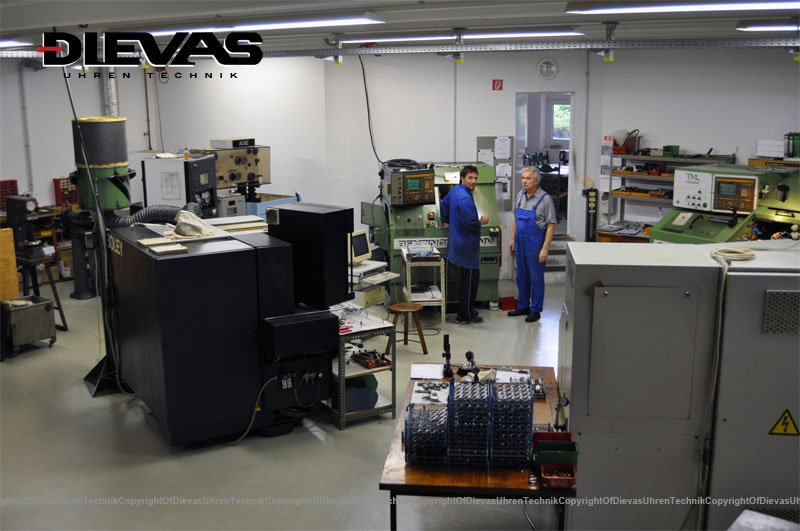

Part of our main manufacturing floor. Not a mega place. But complete CNC machinery for all our manufacturing needs.

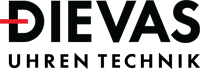

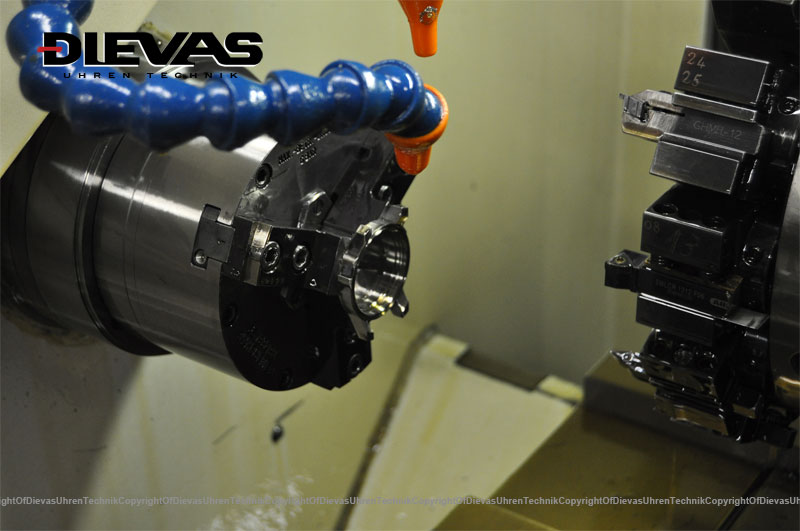

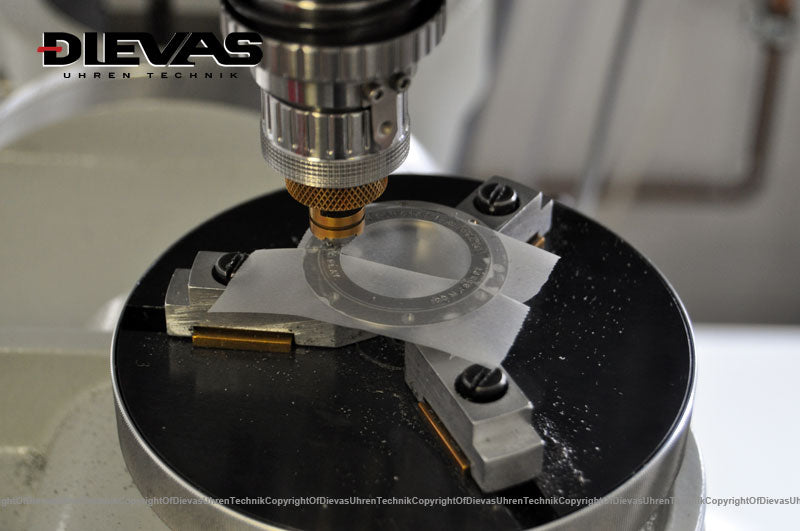

Today I will like to show you the first step of our milling process. And this is the CNC milling machine we will use for the main case. And for the milling of the back of the main case

Clamping the watch case(dial side down) down onto the spindle. To the right of the picture, you can see the multiple milling cutters needed just for the milling of the back of the case.

What processes you ask?

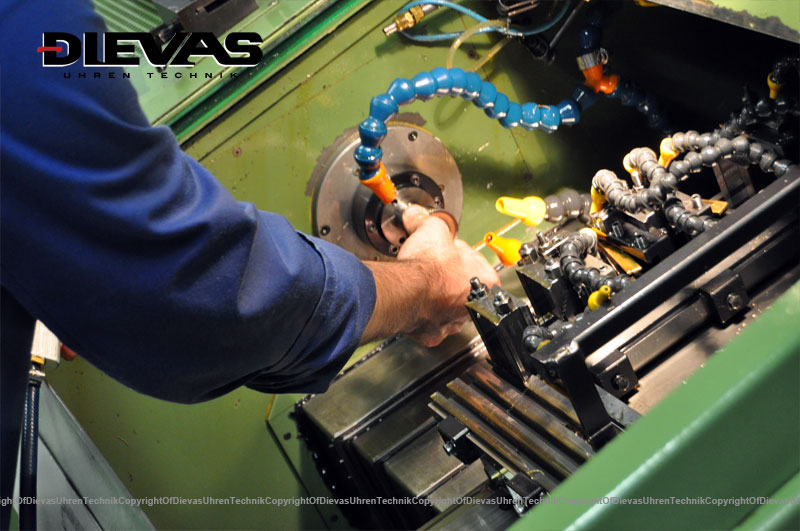

Milling the grooves for the caseback to screw into, milling the shape and angles of the lugs. Different angles and different groove depths uses different cutters. What might look like a simple case does have a lot going on behind the scene.

Closing the shutter and the milling process begins.

And finally, to wrap it all up. A short video to show what goes on and also the music made by the milling machine. What happens is the case clamped on the spindle is turning at high speed. And the cutter approaches it to mill it.

installment

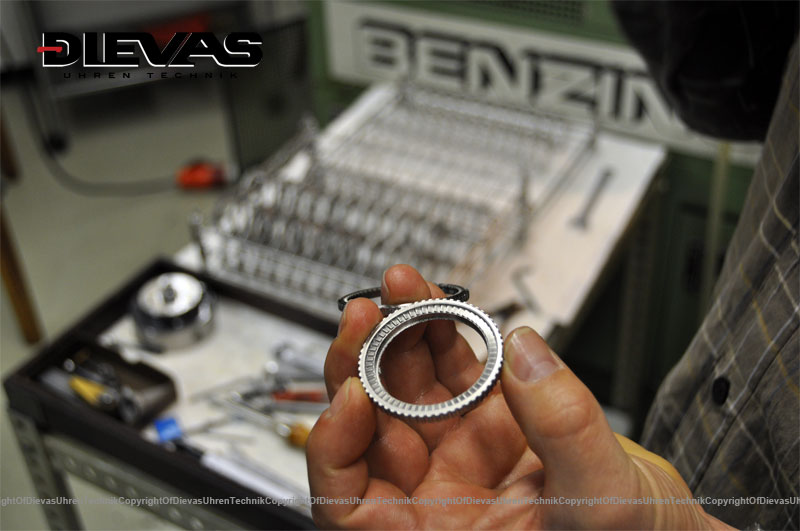

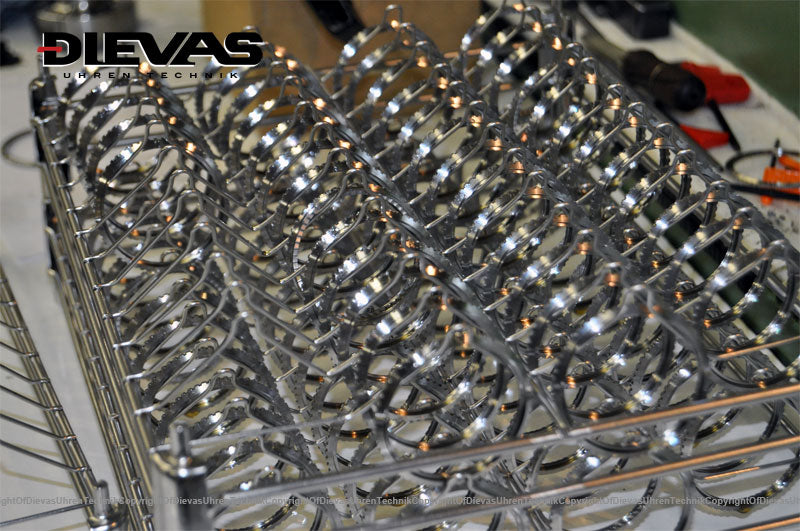

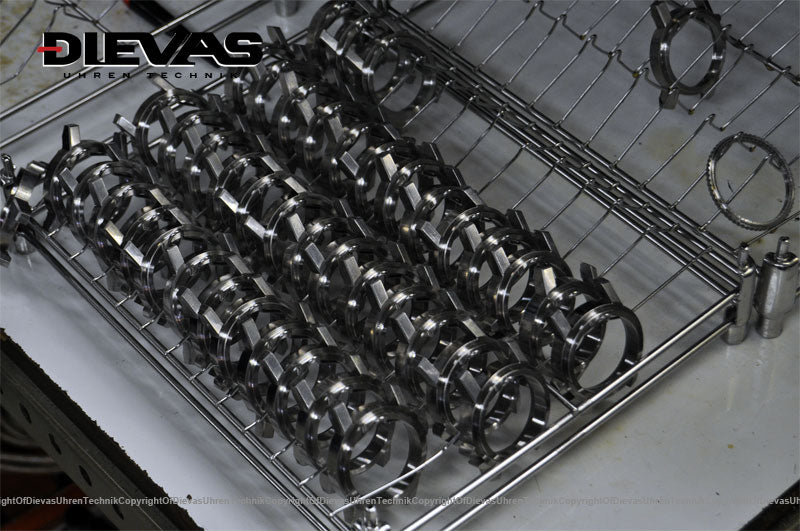

In this installment of The Making of New Dievas Focal – 6Steel, we will be concentrating on the manufacturing of the bezel, the fine gear cutting, the smooth teeth on the bezel among others.The Dievas Focal was conceptualized and designed together with a diving professional. The bezel on the Focal is slightly enlarged and the teeth around the bezel made more pronounced for easy grip and operation underwater.As a seasoned diver, the timing instrument (watch) is probably something you don’t take much care of when you are diving. And so we decided to use our proprietary scratch resistant 6Steel technology for all the exposed parts of the watch. The bezel, the case and the caseback are all made from Dievas 6Steel.

Once again, we are proud to say our watches are MADE IN GERMANY!

In this installment of The Making of New Dievas Focal – 6Steel, we will be walk you through the finishing of all Dievas watches. This is probably the most important procedure of watchmaking.

The step that most big watch companies put the most emphasis on.

The step that determines how the final watch looks.

The step that differentiates us.

The procedure that requires the most hands-on and experience.

And from this installment you will realize Dievas watch is an artform and something you can call HANDMADE IN GERMANY.

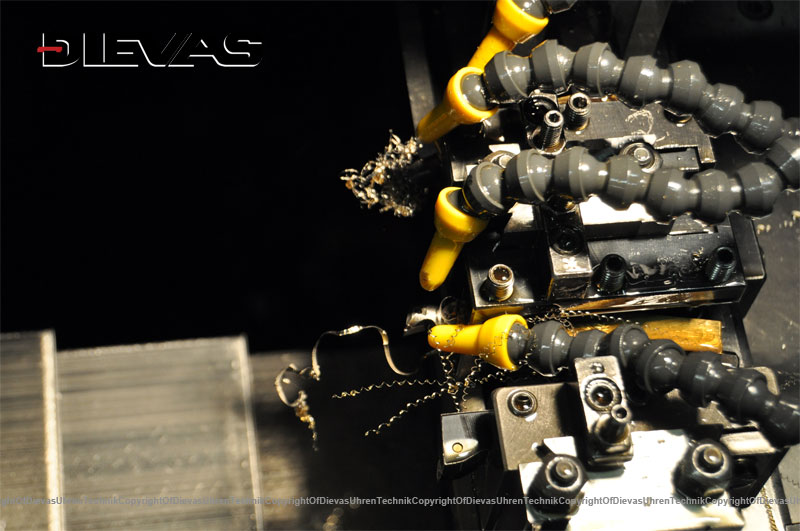

1. After the cases are machined. This is the next step carried out by our watchmaker who has more than 30 years of experience. Something not everyone can carry out. Someone who has an eye for the smallest of details. What we are doing here is putting the watch onto a turning lathe. And finishing the inside of the case. A step that we are proud to say we carry out. After machining of the case, there might still be some small shavings left on the case. And if left there, they might drop into the movement after prolonged use, affecting operations and accuracy of the movement. If you have a chance to see the inside of a Dievas watch. You can see that nothing is left unfinished.

The next step is the polishing and brushing of the watch case. A step that we still carry out even if our watches are sandblasted. This get rids of any machining lines. Look through some of your sandblasted watches and you will understand and appreciate this better. This digitally controlled multi-speed buffing machine is able to control the final looks and result we need. From fine polished to high polished. From fine satin brush to medium satin brush. And of course the experience of our watchmaker plays an important role.

After all is done, the watch is fine beadblasted.

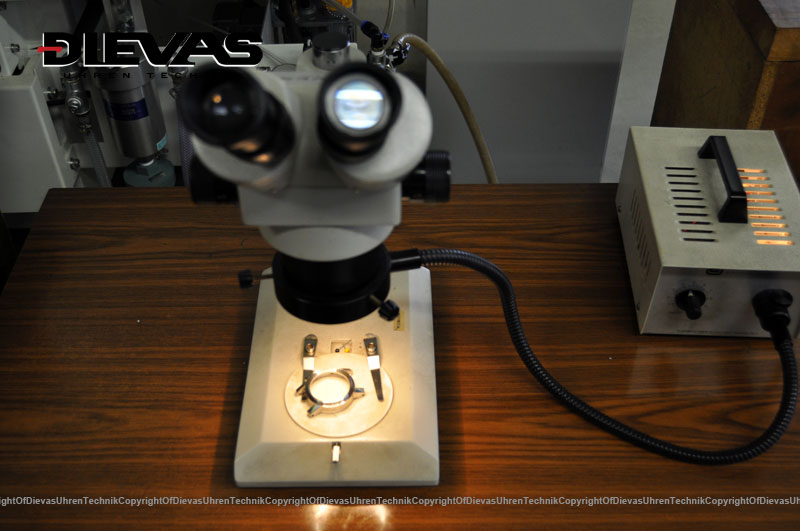

And the final step to check the cases for integrity and tolerance on the microscope and micrometer. To make sure that there are no deviation after all the finishing processes.

Although many steps look redundant as you might not see it. But the owners will appreciate it many months down the road. The steps that ensure the watches still run as accurately as day one. The steps that determine how the watch look.

A Dievas watch is an heirloom you will be proud of to pass it on to your son.